Beta PVC-U Pressure Pipes & Fittings

Reliable & Durable

Light Weight

Corrosion Resistant

Share Via

Beta PVC-U pressure pipes are manufactured in conformity with BS 3505:1968 & 1986, BS 3506:1969 and PS 3051:1991. Beta PVC-U pressure pipes are used for drinking water distribution. The high strength-to-weight ratio, coupled with corrosion resistance, makes these pipes ideal for major infrastructure applications. Additionally, we offer customized solutions based on the requirements of our valued clients and possess the expertise to manufacture in accordance with other international standards such as ASTM D1785 (Schedule 40, 80 & 120), ASTM D 2241, DIN 8061/62 & ISO 161.

▪ Resistant to elements injurious to health i.e. free from corrosion, abrasion, growth of

bacteria, algae and fungi.

▪ Installation is easy as the weight is low and the simplicity to join reduces the installation time, which ultimately makes it cost effective.

▪ High flow capabilities since PVC-U pipes are non-corrosive and inert to chemical or

electrochemical resistance.

▪ It does not support combustion.

▪ Thermally and electrically insulated.

▪ It doesn’t affect the taste, odor, or smell of drinking water.

▪ Cold potable water distribution systems

▪ Agriculture, Horticulture and Greenhouse Irrigation System

▪ Tube wells

▪ Fire-ring mains

▪ Effluent pipelines for pumped sewage, industrial and rural wastes.

▪ Slurry pipelines carrying abrasive and corrosive mine or quality material.

▪ Electrical cable safety system.

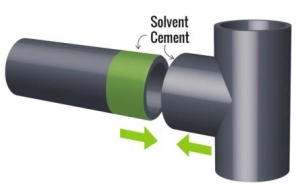

▪ Solvent Cement Jointing

Solvent cement jointing is a welding not a gluing process. Priming fluid and solvent cements

work by softening the surfaces, so when they are brought together the two PVC surfaces

bond together.

▪ Rubber Ring/Push-Fit Jointing

Push-fit fittings are remarkably easy to use and require no particular skill and no dangerous torches or solvents. The fittings are engineered with a rubber ring of metal spurs inside the fittings that tightly grip the pipes when they are inserted into the fitting sockets. Rubber O- rings inside the fittings form tight, waterproof seals against the pipes.

▪ Mechanical Jointing

Mechanical assembly requires the use of fittings, generally working on the compression

principle. It is normally used with PVC for joining the PVC-U to a pipe or fitting of a different material.

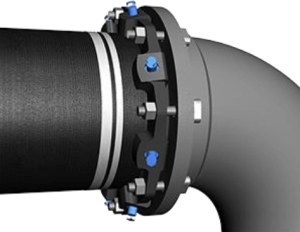

▪ Flange Joint Connection

Flange connection is used for connecting PVC-U pipes to cast iron or galvanized steel or

valves and appurtenances.

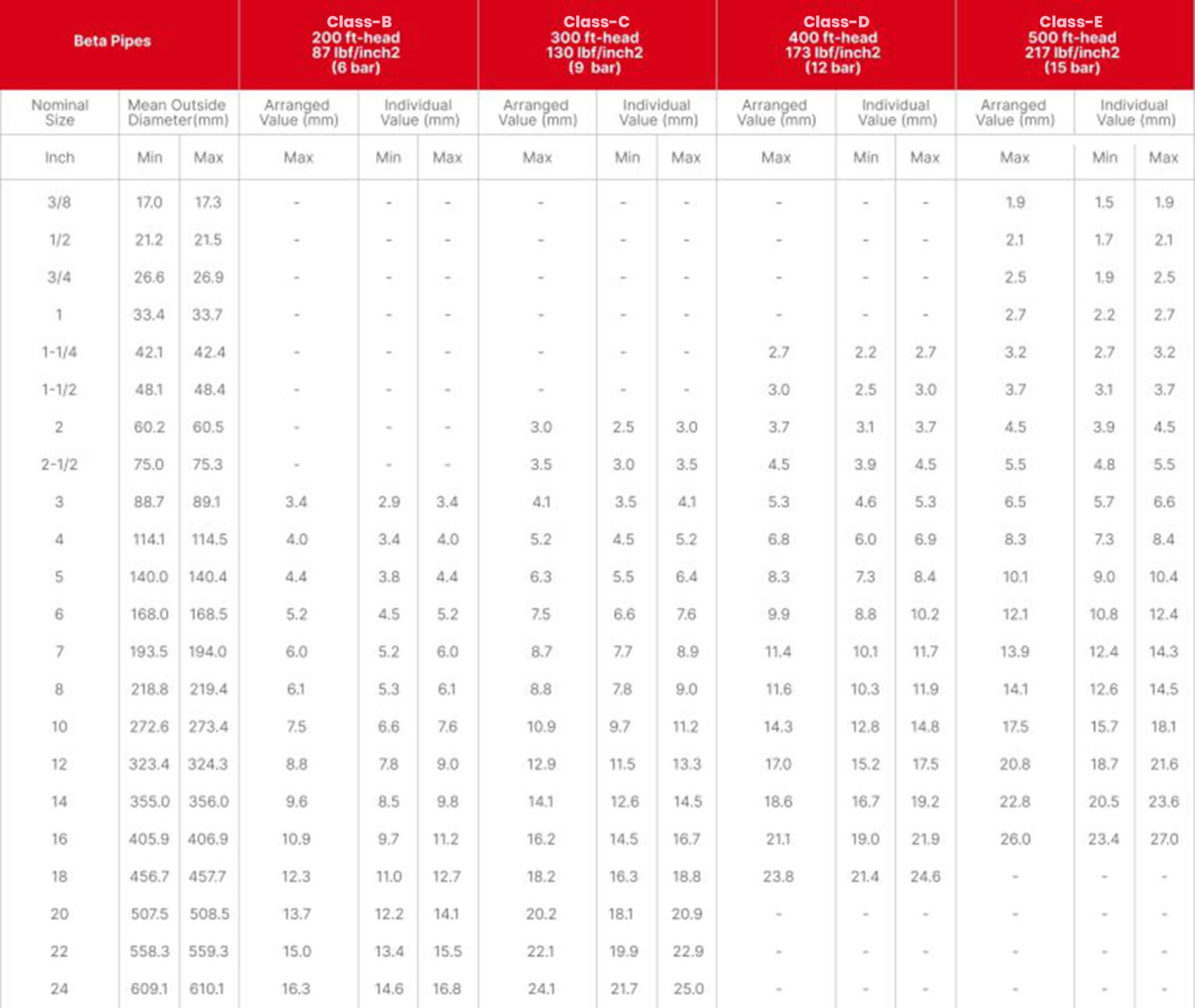

Dimensions

- BS 3505:1968 / PS 3051:1991

- Pressure Temperature Relationship

- ASTM D-1785 (Schedule 40)

- ASTM D-1785 (Schedule 80)

- DIN 8061/62

- ASTM D-2241

| 20°C 68°F | 30°C 86°F | 40°C 104°F | 50°C 122°F | 60°C 140°F | |

|---|---|---|---|---|---|

| B-Class | Meter Head: 60 MPa: 0.60 psi: 87 | Meter Head: 48 MPa: 0.48 psi: 69 | Meter Head: 36 MPa: 0.36 psi: 52 | Meter Head: 24 MPa: 0.24 psi: 59 | Meter Head: 12 MPa: 0.12 psi: 17 |

| C-Class | Meter Head: 90 MPa: 0.90 psi: 130 | Meter Head: 72 MPa: 0.72 psi: 104 | Meter Head: 54 MPa: 0.54 psi: 78 | Meter Head: 36 MPa: 0.36 psi: 52 | Meter Head: 18 MPa: 0.18 psi: 26 |

| D-Class | Meter Head: 120 MPa: 1.20 psi: 173 | Meter Head: 96 MPa: 0.90 psi: 139 | Meter Head: 72 MPa: 0.72 psi: 104 | Meter Head: 48 MPa: 0.48 psi: 69 | Meter Head: 24 MPa: 0.24 psi: 35 |

| E-Class | Meter Head: 150 MPa: 1.50 psi: 217 | Meter Head: 120 MPa: 1.20 psi: 173 | Meter Head: 90 MPa: 0.90 psi: 130 | Meter Head: 60 MPa: 0.60 psi: 87 | Meter Head: 30 MPa: 0.30 psi: 44 |

| Nominal Size | Mean Outside Diameter (mm) | Schedule 40 | ||||

|---|---|---|---|---|---|---|

| Min.(mm) | Max.(mm) | Min. (mm) | Max. (mm) | Working Pressure PSI @ 23°C | ||

| 1/2 | 21.34 | 21.34 | 2.77 | 3.28 | 600 | |

| 3/4 | 26.67 | 26.67 | 2.87 | 3.38 | 480 | |

| 1 | 33.4 | 33.4 | 3.38 | 3.89 | 450 | |

| 1-1/4 | 42.16 | 42.16 | 3.56 | 4.07 | 370 | |

| 1-1/2 | 48.28 | 48.28 | 3.68 | 4.19 | 330 | |

| 2 | 60.32 | 60.32 | 3.91 | 4.42 | 280 | |

| 2-1/2 | 73.02 | 73.02 | 5.16 | 5.77 | 300 | |

| 3 | 88.9 | 88.9 | 5.49 | 6.15 | 260 | |

| 4 | 114.3 | 114.3 | 6.02 | 6.73 | 220 | |

| 5 | 141.3 | 141.3 | 6.55 | 7.34 | 190 | |

| 6 | 168.28 | 168.28 | 7.11 | 7.97 | 180 | |

| 8 | 219.08 | 219.46 | 8.18 | 9.17 | 160 | |

| 10 | 273.05 | 273.43 | 9.27 | 10.39 | 140 | |

| 12 | 323.85 | 324.23 | 10.31 | 11.55 | 130 | |

| 14 | 355.6 | 355.98 | 11.1 | 12.45 | 130 | |

| 16 | 406.4 | 406.88 | 12.7 | 14.22 | 130 | |

| Nominal Size (Inches) | Mean Outside Diameter (mm) | Schedule 80 | ||||

|---|---|---|---|---|---|---|

| Min.(mm) | Max.(mm) | Min. (mm) | Max. (mm) | Working Pressure PSI @ 23°C | ||

| 1/2 | 21.34 | 21.34 | 3.73 | 4.24 | 850 | |

| 3/4 | 26.67 | 26.67 | 3.91 | 4.42 | 690 | |

| 1 | 33.4 | 33.4 | 4.55 | 5.08 | 630 | |

| 1-1/4 | 42.16 | 42.16 | 4.85 | 5.43 | 520 | |

| 1-1/2 | 48.28 | 48.28 | 5.08 | 5.69 | 470 | |

| 2 | 60.32 | 60.32 | 5.54 | 6.2 | 400 | |

| 2-1/2 | 73.02 | 73.02 | 7.01 | 7.85 | 420 | |

| 3 | 88.9 | 88.9 | 7.62 | 8.53 | 370 | |

| 4 | 114.3 | 114.3 | 8.56 | 9.58 | 320 | |

| 5 | 141.3 | 141.3 | 9.52 | 10.66 | 290 | |

| 6 | 168.28 | 168.28 | 10.97 | 12.29 | 280 | |

| 8 | 219.08 | 219.46 | 12.7 | 14.22 | 250 | |

| 10 | 273.05 | 273.43 | 15.06 | 16.86 | 230 | |

| 12 | 323.85 | 324.23 | 17.45 | 20.25 | 230 | |

| 14 | 355.6 | 355.98 | 19.06 | 21.35 | 220 | |

| 16 | 406.4 | 406.88 | 21.41 | 23.98 | 220 | |

| Nominal size (mm) | ||||

|---|---|---|---|---|

| Series 2 (PN-4) | Series 3 (PN-6) | Series 4 (PN-10) | Series 5 (PN-16) | |

| Outside Diameter (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) | Wall Thickness (mm) |

| 63 | – | 1.9 | 3.0 | 4.7 |

| 75 | 1.8 | 2.2 | 3.6 | 5.6 |

| 110 | 2.2 | 3.2 | 5.3 | 8.2 |

| 160 | 3.2 | 4.7 | 7.7 | 11.9 |

| 180 | 3.6 | 5.3 | 8.6 | 13.4 |

| 200 | 4.0 | 5.9 | 9.6 | 14.8 |

| 225 | 4.5 | 6.6 | 10.8 | 16.7 |

| 250 | 4.9 | 7.3 | 11.9 | 18.6 |

| 315 | 6.2 | 9.2 | 15.0 | 23.4 |

| 355 | 7.0 | 10.4 | 16.9 | 26.3 |

| 400 | 7.9 | 11.7 | 19.1 | 29.7 |

PVC-U Pressure Rated Pipes SDR Series for Cold Potable water as per ASTM D-2241

| Nominal Pipe size | Outside Diameter (mm) | SDR-41 Wall Thickness (mm) | SDR-32.5 Wall Thickness (mm) | SDR-26 Wall Thickness (mm) | SDR-21 Wall Thickness (mm) | SDR-13.5 Wall Thickness (mm) |

|---|---|---|---|---|---|---|

| 1/2 | 21.34 | – | – | – | – | 1.6 |

| 3/4 | 26.67 | – | – | – | 1.5 | 2.0 |

| 1 | 33.4 | – | – | 1.5 | 1.6 | 2.5 |

| 1-1/4 | 42.16 | – | 1.5 | 1.6 | 2.0 | 3.1 |

| 1-1/2 | 48.28 | – | 1.5 | 1.9 | 2.3 | 3.6 |

| 2 | 60.32 | – | 1.9 | 2.3 | 2.9 | 4.5 |

| 2-1/2 | 73.02 | – | 2.2 | 2.8 | 3.5 | 5.4 |

| 3 | 88.9 | 2.2 | 2.7 | 3.4 | 4.2 | 6.6 |

| 4 | 114.3 | 2.8 | 3.5 | 4.4 | 5.4 | 8.5 |

| 6 | 168.28 | 4.1 | 5.2 | 6.5 | 8.0 | 12.5 |

| 8 | 219.08 | 5.3 | 6.7 | 8.4 | 10.4 | – |

| 10 | 273.05 | 6.6 | 8.4 | 10.5 | 13.0 | – |

| 12 | 323.85 | 7.9 | 9.9 | 12.5 | 15.4 | – |

| 14 | 355.6 | 8.7 | 10.9 | 13.7 | 16.9 | – |

| 16 | 406.4 | 9.9 | 12.5 | 15.6 | 19.3 | – |

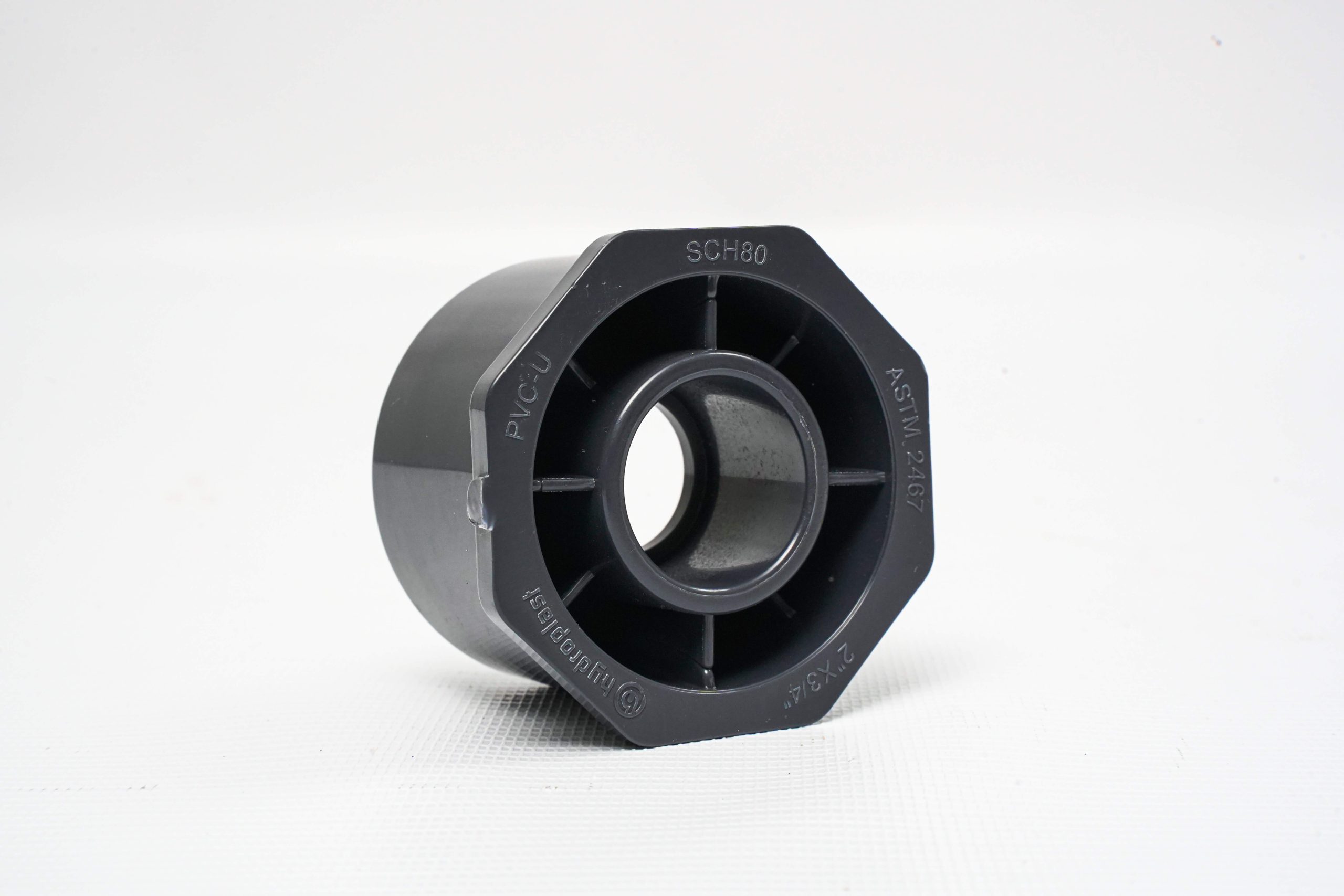

PVC-U Pressure Fittings

Ball Valve

End Cap

Socket

Union Type Socket

Flange

Reducing Bush

Fabricated Socket

Elbow

Cuppling Gate Valve

Butterfly Valve

Union

Threaded Bush

Reducing TEE

TEE

Fabricated Bend