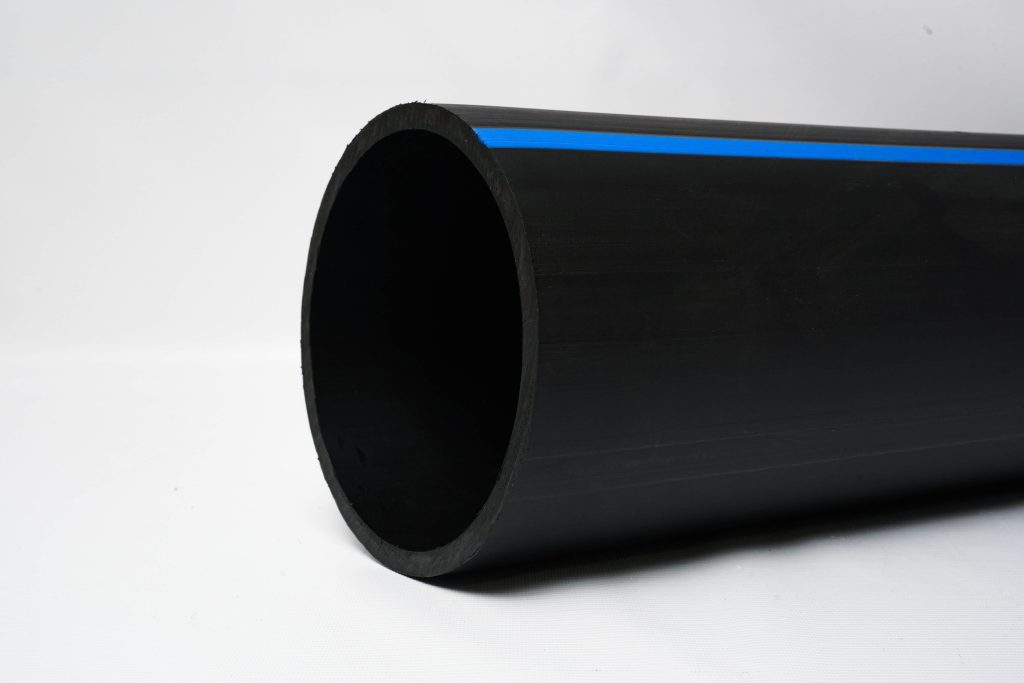

Beta PE-100 Pressure Pipes & Fittings

Reliable & Durable

Flexible

Non-Corrosive

Environment Friendly

Share Via

Polyethylene pipes & fittings have a proven high reliability record across a wide range of industries and applications. Beta Pipes has gained a reputation as a quality supplier of thermoplastic pipe systems and solutions, sustained by a determined commitment to utilizing the highest standard of raw materials and cutting-edge manufacturing technology, Inclusive PVC-U, PPRC, and now Polyethylene (PE-100).

Polyethylene piping is a cost-effective solution addressing a broad range of piping challenges in municipal, industrial, marine, mining, landfill, duct, and agriculture applications.

The Beta PE-100 is capable of transporting potable water, wastewater, slurries, chemicals, and hazardous waste.

- Abrasion Resistance- Beta PE pipes have excellent abrasion resistance, ensuring a long lifespan in applications involving abrasive slurries.

- Chemical Resistance- Beta PE pipes have outstanding chemical resistance against a broad range of chemical reagents.

- Flexibility – The flexibility and resiliency of Beta PE pipes enable them to absorb surge pressure, vibration, and stresses caused by soil movement.

- Ease of Installation- Beta PE pipes are designed to facilitate easy installation, aided by their lightweight nature and extended lengths, thereby minimizing the need for additional joints.

- High Flow Capacity- Low friction compared with materials such as fiber reinforcement cement and resistance to material deposit build-up give PE pipe long-lived high flow capacity.

- Weathering Resistance – Beta PE pipes, stabilized against UV light degradation, show weathering resistance, making them suitable for above-ground installations.

- Cost Saving with faster Installation – Leak tight, fully fused joints.

- Long Life - PE pipes have proven reliability across arrange of applications, around 50 years.

▪ Better suit for piping systems in areas with seismic activity.

▪ Wastewater facility outfall pipes and storm water applications

▪ Mining, Oil, gas and municipal distribution applications.

▪ Sewage systems because they are less likely to leak or burst.

The four types of jointing commonly used for jointing BETA PE-100 pipes & fittings are,

▪ Electrofusion

In situations where butt fusion is impractical, such as when valves, elbows, and tees need to be

added, electrofusion provides a straightforward technique for joining PE pipes. Utilizing

prefabricated fittings with an electrical heating coil, the plastic of the pipe and the fitting are

melted and fused together.

▪ Butt fusion

Butt Fusion is a thermofusion process most common jointing process involves the

simultaneous heating of ends of two pipe/fitting components which are to be joined, until a

molten state is attained on each contact surface.

The two surfaces are then brought together under controlled pressure for a specific cooling

time and a homogeneous fusion joint is formed. The resultant joint is fully resistant to end

loads and has comparable performance under pressure to the pipe itself.

▪ Compression Coupling

Compression fittings are normally available only relatively in small diameters. Mechanical

assembly requires the use of fittings, generally working on the compression principle. It is

most commonly used with PE for joining the PE to a pipe or fitting of a different material, or in circumstances where fusion is not feasible and this joining method is not recommended for

pipes with diameters are exceeding 110mm.

▪ Flange Joint

Connection Flange connection is used for connecting HDPE pipes to cast iron or galvanized steel or valves and appurtenances. This connection is composed of an HDPE conversion, one end of

which is flanged and the other end is simple and of a perforated metal ring used in where pipe line need to be dismantled at a later stage or connecting PE pipes to different materials.

Dimensions

- DIN 8074/75

- PS3580

- ISO 4427

BETA PE-100 pipes, designed for potable water applications, comply with international standards including DIN 8074, PS 3580 & ISO 4427. The normal pressure (PN) corresponds to the maximum allowable working pressure in bars for the pipe at 20°C.

| DN | SDR 11 (PN 16) | SDR 13.6 (PN 12.5) | SDR 17 (PN 10) | SDR 21 (PN 8) |

|---|---|---|---|---|

| Outer diameter (mm) | e (mm) | e (mm) | e (mm) | e (mm) |

| 20 | 1.9 | 1.8 | – | – |

| 25 | 2.3 | 2.0 | 1.8 | – |

| 32 | 2.9 | 2.4 | 1.9 | – |

| 40 | 3.7 | 3.0 | 2.4 | 1.9 |

| 50 | 4.6 | 3.7 | 3.0 | 2.4 |

| 63 | 5.8 | 4.7 | 3.8 | 3.0 |

| 75 | 6.8 | 5.6 | 4.5 | 3.6 |

| 90 | 8.2 | 6.7 | 5.4 | 4.3 |

| 110 | 10.0 | 8.1 | 6.6 | 5.3 |

| 125 | 11.4 | 9.2 | 7.4 | 6.0 |

| 140 | 12.7 | 10.3 | 8.3 | 6.7 |

| 160 | 14.6 | 11.8 | 9.5 | 7.7 |

| 180 | 16.4 | 13.3 | 10.7 | 8.6 |

| 200 | 18.2 | 14.7 | 11.9 | 9.6 |

| 225 | 20.5 | 16.6 | 13.8 | 10.8 |

| 250 | 22.7 | 18.4 | 14.8 | 11.9 |

| 315 | 28.6 | 23.2 | 18.7 | 15.0 |

BETA PE-100 pipes for potable water application are manufactured according to international Standard, DIN8074, PS3580 & ISO 4427. The normal pressure (PN) corresponds to the maximum allowable working pressure in bar for pipe at 20C.

| DN | SDR 11 (PN 16) | SDR 13.6 (PN 12.5) | SDR 17 (PN 10) | SDR 21 (PN 8) |

|---|---|---|---|---|

| Outer diameter (mm) | e (mm) | e (mm) | e (mm) | e (mm) |

| 20 | 1.9 | 1.8 | – | – |

| 25 | 2.3 | 2.0 | 1.8 | – |

| 32 | 2.9 | 2.4 | 1.9 | – |

| 40 | 3.7 | 3.0 | 2.4 | 1.9 |

| 50 | 4.6 | 3.7 | 3.0 | 2.4 |

| 63 | 5.8 | 4.7 | 3.8 | 3.0 |

| 75 | 6.8 | 5.6 | 4.5 | 3.6 |

| 90 | 8.2 | 6.7 | 5.4 | 4.3 |

| 110 | 10.0 | 8.1 | 6.6 | 5.3 |

| 125 | 11.4 | 9.2 | 7.4 | 6.0 |

| 140 | 12.7 | 10.3 | 8.3 | 6.7 |

| 160 | 14.6 | 11.8 | 9.5 | 7.7 |

| 180 | 16.4 | 13.3 | 10.7 | 8.6 |

| 200 | 18.2 | 14.7 | 11.9 | 9.6 |

| 225 | 20.5 | 16.6 | 13.8 | 10.8 |

| 250 | 22.7 | 18.4 | 14.8 | 11.9 |

| 315 | 28.6 | 23.2 | 18.7 | 15.0 |

BETA PE-100 pipes for potable water application are manufactured according to international Standard, DIN8074, PS3580 & ISO 4427. The normal pressure (PN) corresponds to the maximum allowable working pressure in bar for pipe at 20C.

| DN | SDR 11 (PN 16) | SDR 13.6 (PN 12.5) | SDR 17 (PN 10) | SDR 21 (PN 8) |

|---|---|---|---|---|

| Outer diameter (mm) | e (mm) | e (mm) | e (mm) | e (mm) |

| 20 | 1.9 | 1.8 | – | – |

| 25 | 2.3 | 2.0 | 1.8 | – |

| 32 | 2.9 | 2.4 | 1.9 | – |

| 40 | 3.7 | 3.0 | 2.4 | 1.9 |

| 50 | 4.6 | 3.7 | 3.0 | 2.4 |

| 63 | 5.8 | 4.7 | 3.8 | 3.0 |

| 75 | 6.8 | 5.6 | 4.5 | 3.6 |

| 90 | 8.2 | 6.7 | 5.4 | 4.3 |

| 110 | 10.0 | 8.1 | 6.6 | 5.3 |

| 125 | 11.4 | 9.2 | 7.4 | 6.0 |

| 140 | 12.7 | 10.3 | 8.3 | 6.7 |

| 160 | 14.6 | 11.8 | 9.5 | 7.7 |

| 180 | 16.4 | 13.3 | 10.7 | 8.6 |

| 200 | 18.2 | 14.7 | 11.9 | 9.6 |

| 225 | 20.5 | 16.6 | 13.8 | 10.8 |

| 250 | 22.7 | 18.4 | 14.8 | 11.9 |

| 315 | 28.6 | 23.2 | 18.7 | 15.0 |

PP Compression and PE-100 Butt-Fusion (B/F) Fittings

Compression TEE

Cross

End Cap

Female Elbow

Female Socket

Group Fitting

Male Elbow

Male Socket

Reducer

Stub End

TEE

Bend 45 Degree