Pipes Installation Guidelines

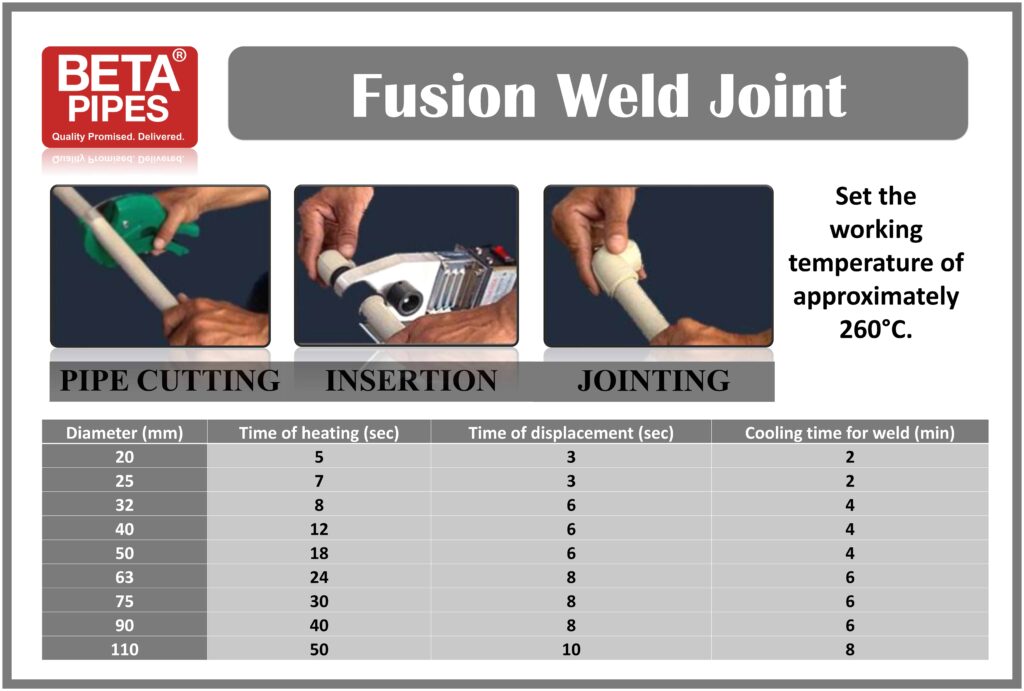

PPRC Pipes Jointing: Fusion Jointed

Welding is the preferred method for connecting PPR pipes due to its strength and durability. Creating a nearly seamless connection involves fusing the ends of the pipes using a specially designed welding machine. Skilled experts typically perform welding due to its requirement for a high level of ability and knowledge. Once the link is established, it proves incredibly durable and impenetrable to leaks and other forms of damage.

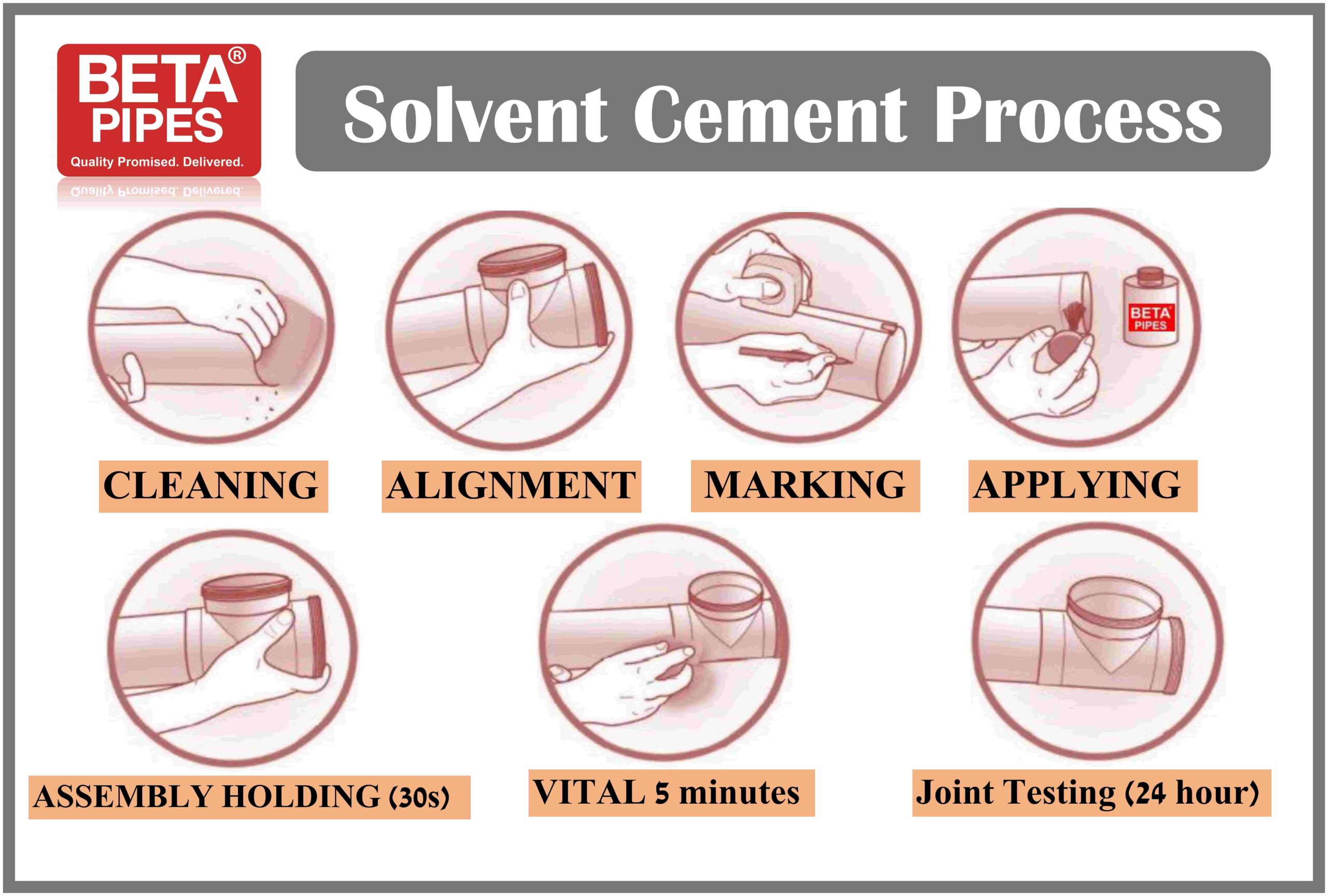

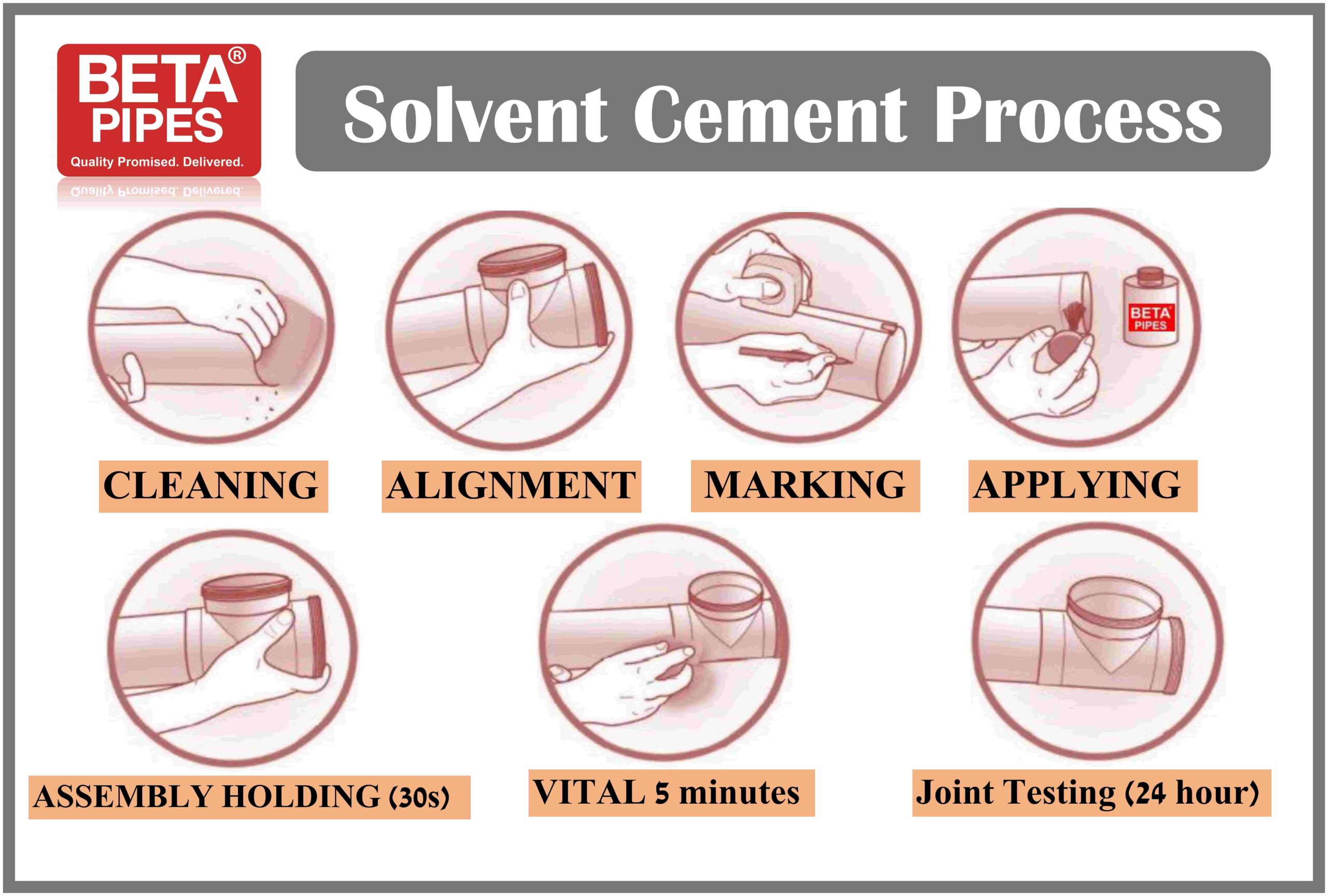

PVC-U SWV Pipes Jointing: Solvent Cement

Solvent cement jointing is a welding process, not gluing. Priming fluid and solvent cements soften the surfaces, allowing the two PVC surfaces to bond together.

PVC-U Pressure Pipes Jointing

Solvent Cement

Solvent cement jointing is a welding process, not gluing. Priming fluid and solvent cement work by softening the surfaces, allowing the two PVC surfaces to bond together when brought together.

Solvent cement jointing is a welding process, not gluing. Priming fluid and solvent cement work by softening the surfaces, allowing the two PVC surfaces to bond together when brought together.

Rubber Ring/Push-Fit

Push-fit fittings are remarkably easy to use, requiring no specific skills or dangerous torches or solvents. Engineered with a rubber ring of metal spurs inside, the fittings tightly grip the pipes upon insertion into the fitting sockets. Rubber O-rings inside the fittings create tight, waterproof seals against the pipes.

Push-fit fittings are remarkably easy to use, requiring no specific skills or dangerous torches or solvents. Engineered with a rubber ring of metal spurs inside, the fittings tightly grip the pipes upon insertion into the fitting sockets. Rubber O-rings inside the fittings create tight, waterproof seals against the pipes.

Pipe Leakages Issues

Persistent leaks can cause structural damage to buildings, leading to costly repairs and potential health hazards from mold growth. Pipe leakage leads to significant water wastage, contributing to environmental strain and increased utility bills. To reduce the tension of pipe leakages. Use Beta Pipe’s quality piping system that fulfills international quality standards.

Our Clients