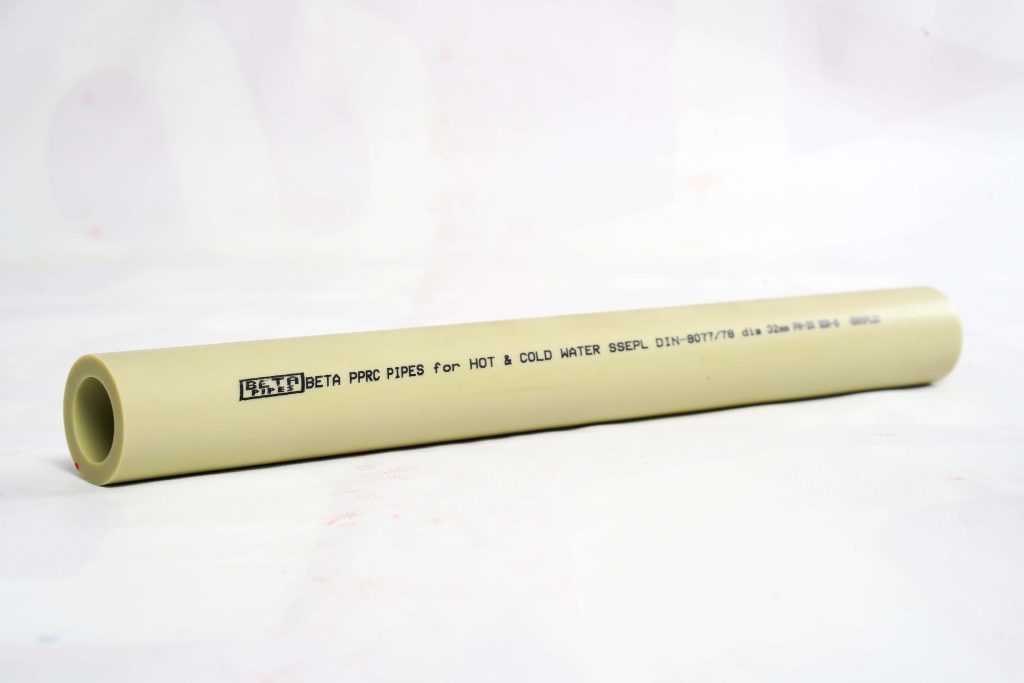

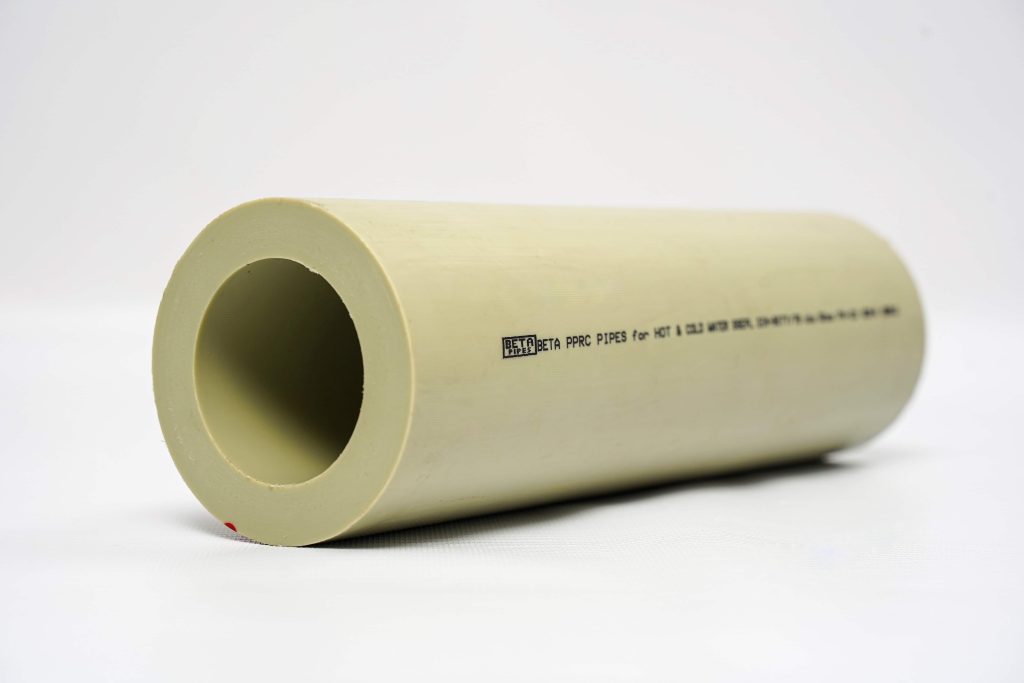

PPR-C Pipes & Fittings (Hot & Cold Water Supply System)

Reliable & Durable

Environment Friendly

Cost Effective

Easy Connectivity

Non-Corrosive

Share Via

The BETA PPR-C piping system stands as an ultimate solution for water and fluid transportation, catering to pressurized hot and cold water delivery, as well as underfloor heating in modern residential apartments, commercial buildings, and diverse industries. Its remarkable resistance to high temperatures and pressures makes it a reliable choice.

- Durable- high resistance to aggressive elements, which gives the system service life of 50 years and more.

- Easy connectivity over a complex network.

- Low Electrical Conductivity

- Resistance to Frost

- Suitable for use in seismic areas.

- Cost Effective pipeline network.

- Environment friendly with recyclable ability.

- Hospitals

- Swimming pools

- Residential apartments, Hotels and shopping complexes.

- Chilled water for central air conditioning systems

- Irrigation systems

Socket Fusion

Welding is the preferred method for connecting PPR pipes due to its strength and durability. Creating a nearly seamless connection involves fusing the ends of the pipes using a specially designed welding machine. Skilled experts typically perform welding due to its requirement for a high level of ability and knowledge. Once the link is established, it proves incredibly durable and impenetrable to leaks and other forms of damage.

For more Information Download our brochure

For more Information Download our brochure

Dimensions

- DIN 8077/8078

- EN ISO 15874

- PS 4533/34

The BETA PPR-C piping system, made from Polypropylene Random Copolymer, a 100% certified Food Grade material, ensures efficiency with its granule characteristics, resulting in extruded pipes featuring smooth internal walls. Manufactured in adherence to DIN 8077/8078, EN ISO 15874 & PS 4533/34 standards

BETA PPR-C piping system has the adjacent range of pipes (20mm-110mm) and complete array of compatible fittings;

| Outer diameter d (mm) | Wall thickness s (mm) | Internal diameter di (mm) |

|---|---|---|

| 20 | 3.4 | 13.2 |

| 25 | 4.2 | 16.6 |

| 32 | 5.4 | 21.2 |

| 40 | 6.7 | 26.6 |

| 50 | 8.4 | 33.2 |

| 63 | 10.5 | 42.0 |

| 75 | 12.5 | 50.0 |

| 90 | 15.0 | 60.0 |

| 110 | 18.4 | 73.2 |

The BETA PPR-C piping system, made from Polypropylene Random Copolymer, a 100% certified Food Grade material, ensures efficiency with its granule characteristics, resulting in extruded pipes featuring smooth internal walls. Manufactured in adherence to DIN 8077/8078, EN ISO 15874 & PS 4533/34 standards

BETA PPR-C piping system has the adjacent range of pipes (20mm-110mm) and complete array of compatible fittings;

| Outer diameter d (mm) | Wall thickness s (mm) | Internal diameter di (mm) |

|---|---|---|

| 20 | 3.4 | 13.2 |

| 25 | 4.2 | 16.6 |

| 32 | 5.4 | 21.2 |

| 40 | 6.7 | 26.6 |

| 50 | 8.4 | 33.2 |

| 63 | 10.5 | 42.0 |

| 75 | 12.5 | 50.0 |

| 90 | 15.0 | 60.0 |

| 110 | 18.4 | 73.2 |

The BETA PPR-C piping system, made from Polypropylene Random Copolymer, a 100% certified Food Grade material, ensures efficiency with its granule characteristics, resulting in extruded pipes featuring smooth internal walls. Manufactured in adherence to DIN 8077/8078, EN ISO 15874 & PS 4533/34 standards

BETA PPR-C piping system has the adjacent range of pipes (20mm-110mm) and complete array of compatible fittings;

| Outer diameter d (mm) | Wall thickness s (mm) | Internal diameter di (mm) |

|---|---|---|

| 20 | 3.4 | 13.2 |

| 25 | 4.2 | 16.6 |

| 32 | 5.4 | 21.2 |

| 40 | 6.7 | 26.6 |

| 50 | 8.4 | 33.2 |

| 63 | 10.5 | 42.0 |

| 75 | 12.5 | 50.0 |

| 90 | 15.0 | 60.0 |

| 110 | 18.4 | 73.2 |

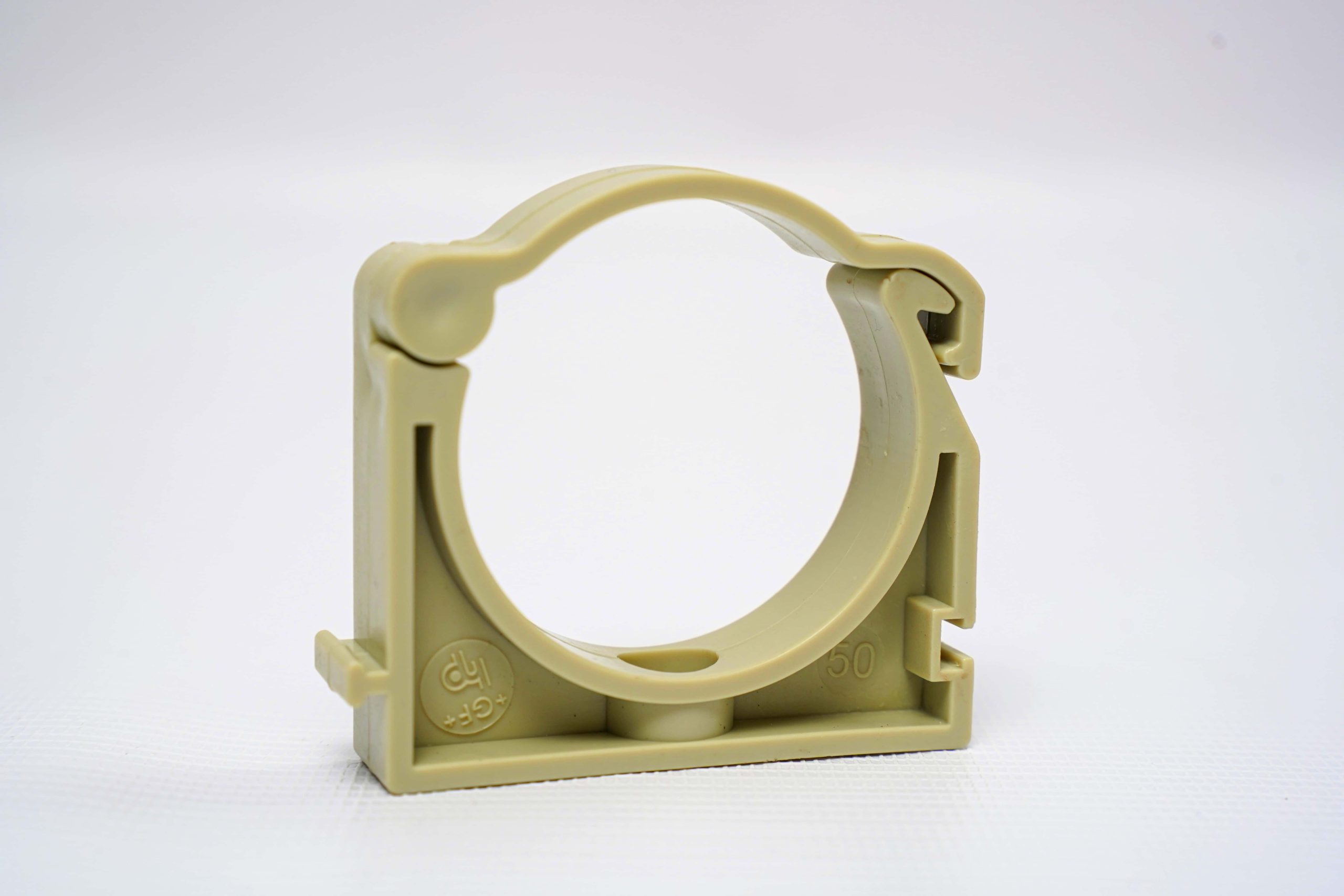

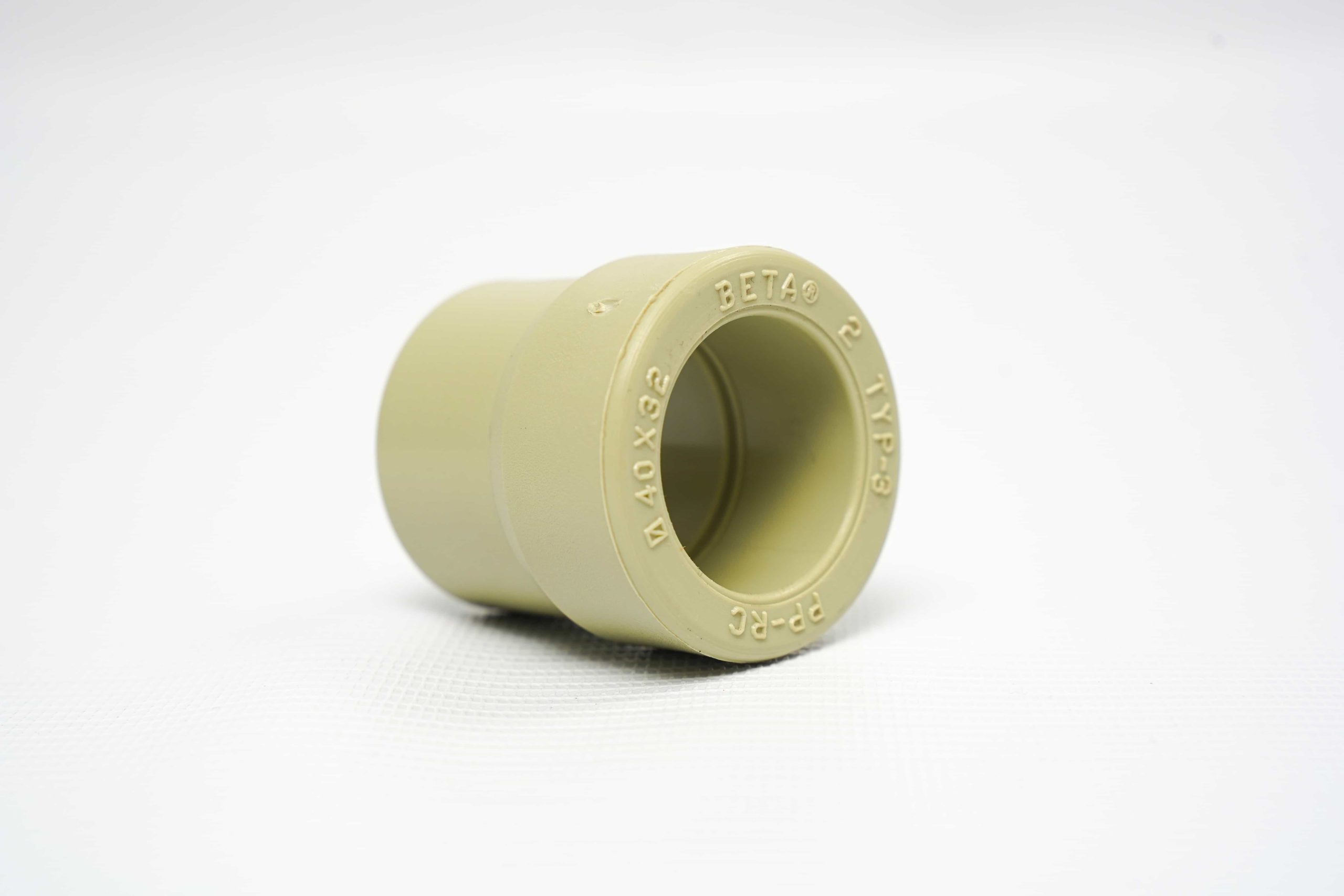

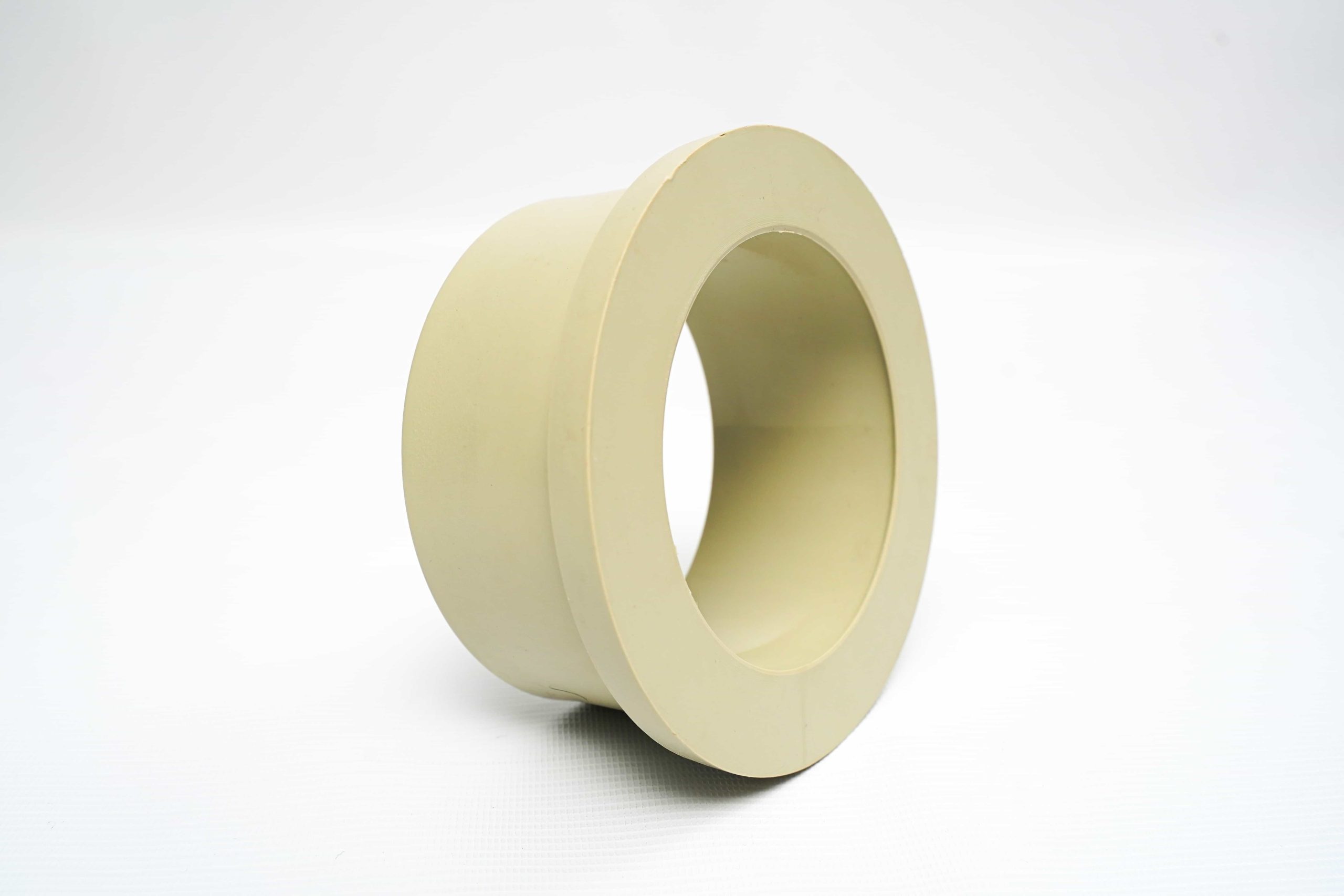

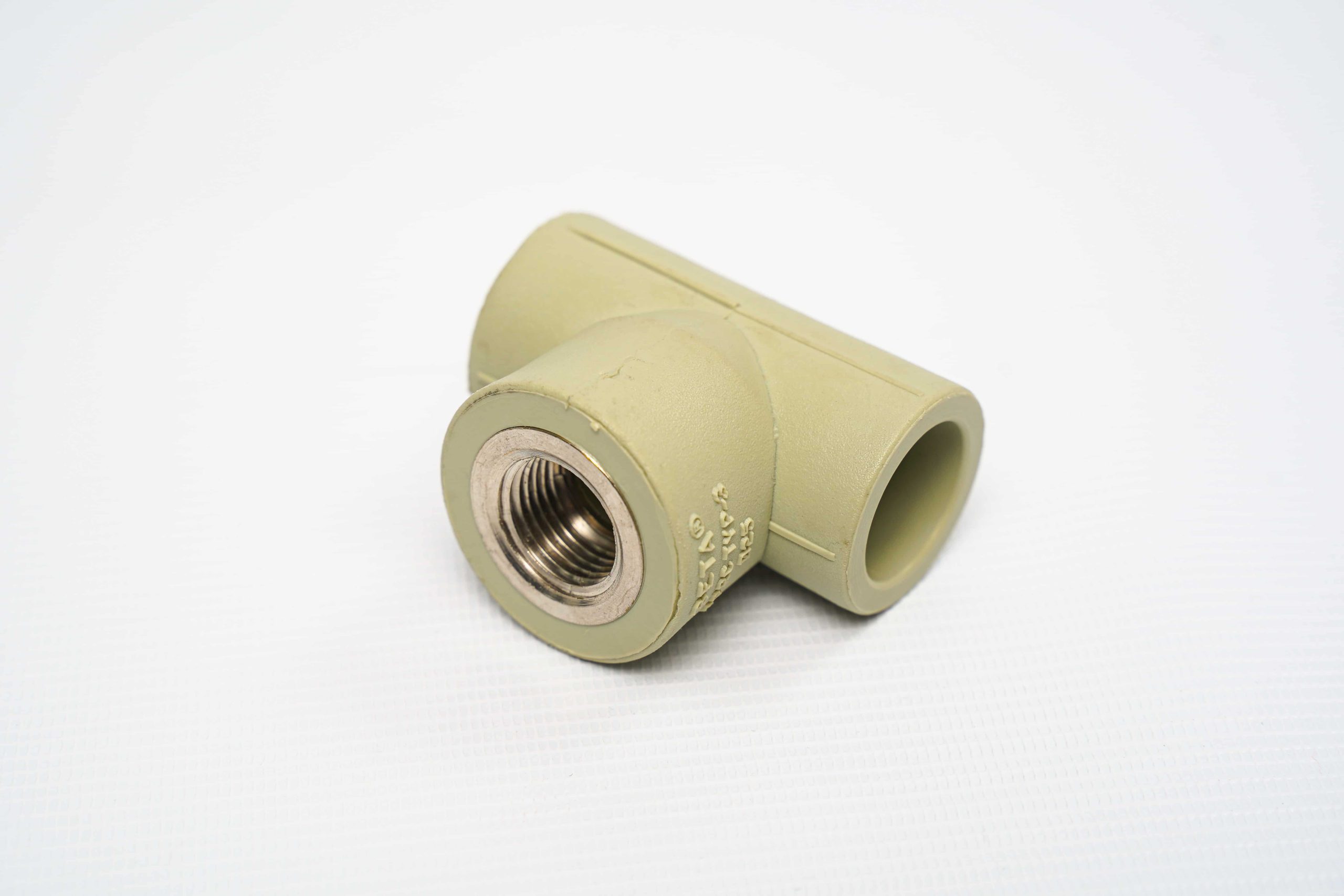

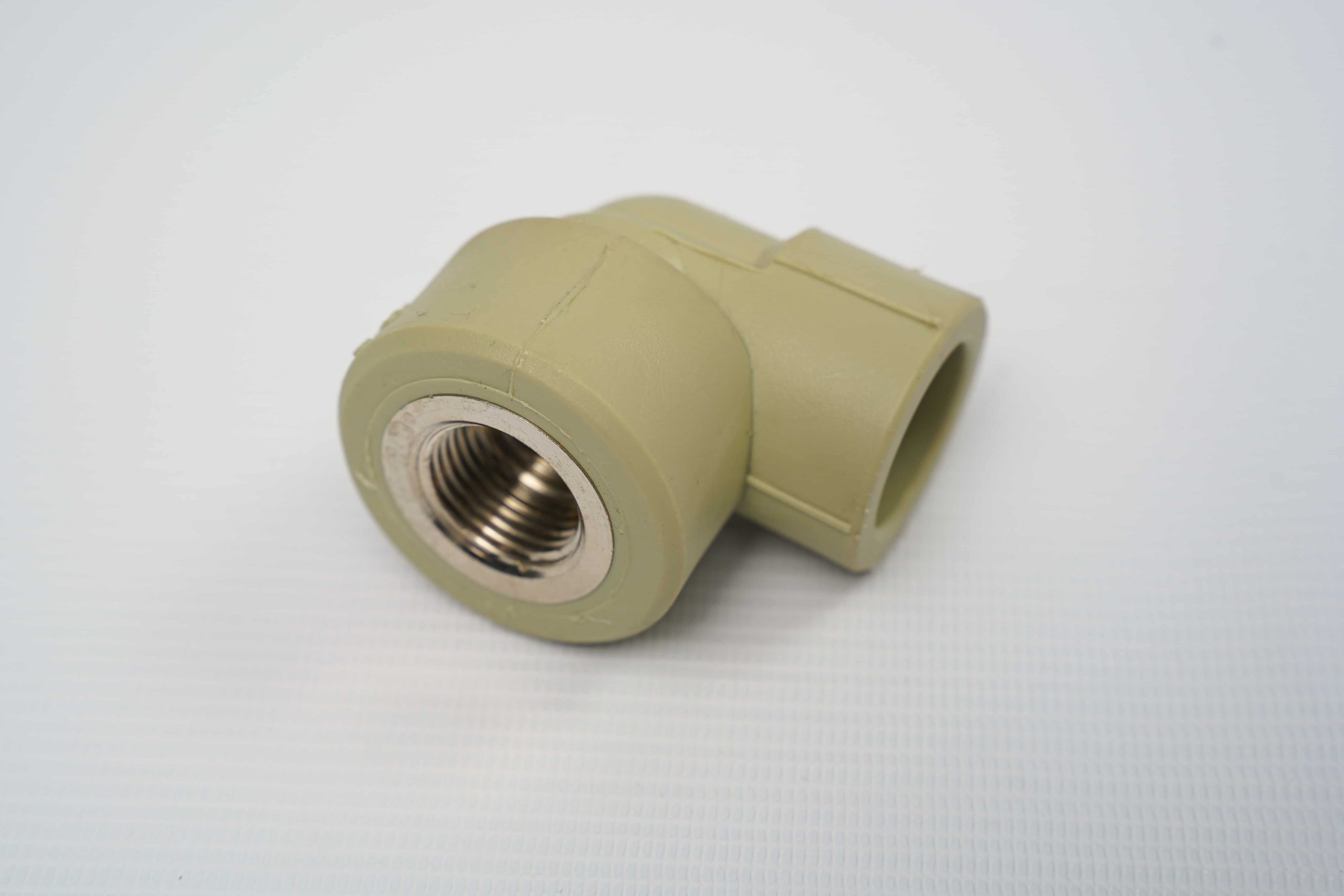

PPR-C Fittings

Wall Clamp

TEE

Socket

Reducing TEE

Reducer

Male Union

Male TEE

Male Elbow

Male Adaptor

Gate Valve

Flange

Female Union

Female TEE

Female Elbow

Female Adaptor

End Cap

Elbow

Cross Over

Blind Cap